SINOCONVE

CONVEYOR BELT CATALOG

PRODUCT DESCRIPTION

Our conveyor belt products are designed to meet various needs from our customers all over the world across industries like pulp and paper, mining, crusher plant, cement, steel, construction and many others. Advanced production technology and extensive working experience enable us to manufacture high quality conveyor belts resisting to impact, abrasion, tear, cut, heat, fire, cold, oil and grease.

PROPERTY

-

Suitable for heavy duty operations due to polyester/polyamide (EP) fabric structure design

-

Low elongation with high reliability and durability

-

High adhesion between layers and between the cover and the layer.

-

Advanced production technologies and facilities ensure conveyor belt extended lifetime

-

Available widths from 300mm to 3100mm, depending on the rubber conveyor belt thickness and length.

-

Different cover quality enable EP conveyor belts to transport materials that are -40℃ to 300℃, flammable, oily and cold.

SPECIFICATIONS

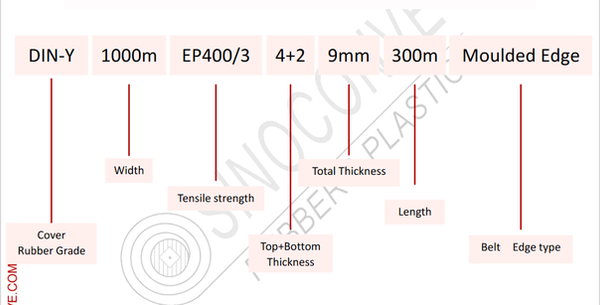

SPECIFICATION

We can provide conventional rubber conveyor belts with the following specifications. If there are special requirements, we could also produce customized conveyor belts based on customer specific inquiries.

FIRE RESISTANT (FLAME RETARDANT) CONVEYOR BELT

For conveying combustible materials such as coal dust, gas, fertilizer, etc., it is very important to choose SINOCONVE fireproof Conveyor belt. It is widely used in wood, paper and pulp, sugar and food, recycling and fertilizer plants.

SINOCONVE manufacture fire resistant conveyor belts according to customer's operational conditions

PROPERTY

-

Anti-static which conforms to EN/ISO 20284 international standards.

-

When ignited, it will self-extinguish within 15 seconds.

-

Rubber belts reinforced by several layers of textile fabrics (multi-ply) or steel cord.

-

Available in abrasion resistant type--as low as 150mm³, oil resistant type for both mineral oil and vegetable oil.

-

Widely used in underground mining industry for long distance transportation with high speed.

-

K grade (with covers) and S grade (with or without covers) are available for fire resistant conveyor belts.

FIRE RESISTANT (FLAME RETARDANT) CONVEYOR BELT

Fire resistance conveyor belt test according to EN/ISO 340:

-

Anti-static: ≦3x108

-

Drum friction: no flame under 325℃ conditions

-

Burning test:

Flame retardant conveyor belt sample

Normal conveyor

belt sample

Put six individual samples of the belt on a naked flame

Put six individual samples of the

belt on a naked flame

The flame goes out within 10 seconds after leaving the fire

Continue to burn after

leaving the fire

A. For individual test samples of fire-resistant conveyor belts, the time required for self-extinguishing shall be no more than 15 seconds.

B. For each group of six test objects, the maximum cumulative time they require to extinguish themselves shall not exceed 45 seconds.

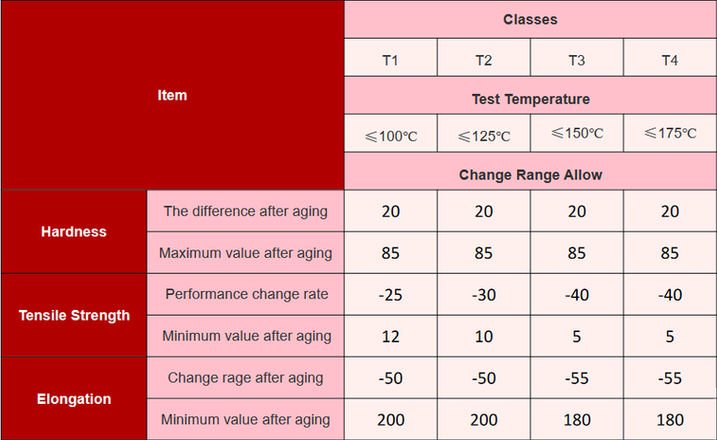

HEAT RESISTANT (HEAT RETARDANT) CONVEYOR BELT

When conveying hot materials, the rubber conveyor belt surface often has direct contact with materials. Conventional conveyor belts will be easily cracked and hardened under this condition. This will reduce the protection of carcass from cover rubber, thus resulting carcass separation and splice failure.

Our heat resistant conveyor belts are tailored with special heat resistant compounds and innovative structure to solve these problems.

Ideal for transporting high-temperature, high-heat raw materials, semi-finished products, and products. If the belt surface temperature exceeds 60℃, heat-resistant conveyor belt is the perfect solution.

HEAT RESISTANT (HEAT RETARDANT) CONVEYOR BELT

PROPERTY

-

Optimal formula of EPDM/POE vulcanizing, together with customized mixing process, to obtain ideal heat resistant cover rubber.

-

Both sides of carcass in heat resistant conveyor belts is covered with special aminolysis reaction resistant fiber material. It not only effectively isolates polyester fiber from direct contact with cover rubber, preventing carcass destruction caused by heat, but also retain a high adhesion to EPDM under high temperature.

-

Anti-aging feature of the special carcass make it no need to increase cover rubber thickness during belt design, resulting in a reduced cover rubber consumption and production cost of heat resistant conveyor belts.

OIL RESISTANT (OIL RETARDANT) CONVEYOR BELT

SINOCONVE oil-resistant conveyor belt is the right choice for transporting oily materials in various kind of plants such as food, animals, plants, and minerals. It is also ideal for high temperature environment in power plants because using conventional conveyor belts at high temperature may greatly shortened conveyor belt lifetime due to the synergistic effect of oil and high temperature.

Volume Change Rate / Type Of Belt

Rapeseed Oil

Kerosene

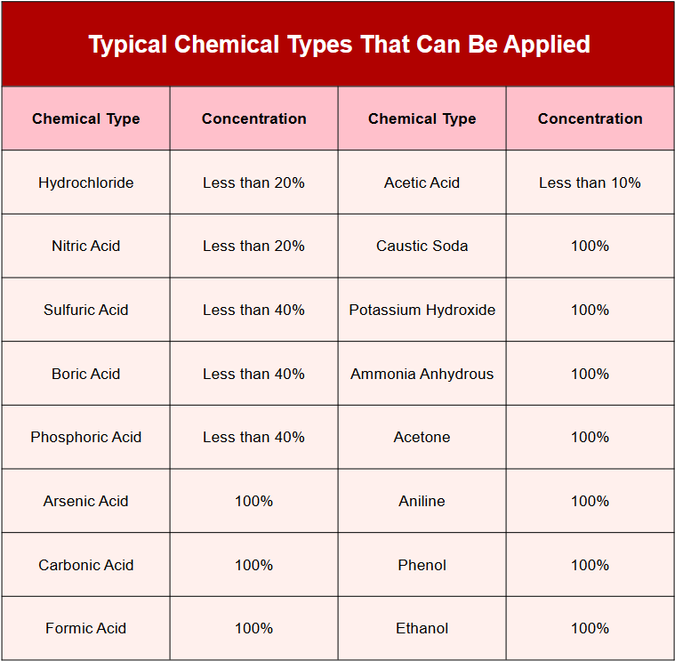

CHEMICAL RESISTANT (ACID/ALKALI RETARDANT) CONVEYOR BELT

SINOCONVE chemical resistant (acid & alkali retardant) conveyor belts is perfect for transporting materials that contains chemical substances or acidic or alkaline materials in chemical plants, pulp & paper mills, cement plants, etc.

For other chemicals, please contact us

ABRASION RESISTANT (ABRASION RETARDANT) CONVEYOR BELT

SINOCONVE abrasion resistant (abrasion retardant) conveyor belt uses rubber with excellent wear resistance, which is suitable for quarries, mines, etc.

For abrasion resistance test, we press a cylindrical sample with a diameter of 16mm and a thickness of about 8mm on a roller wrapped with sandpaper under a certain load. The sample wears when the drum rotates, and the wear after a certain distance is measured.

SINOCONVE Abrasion Resistance Test

-

abrasion resistance Normal conveyor belt, abrasion less than 250mm³.

-

For super abrasion resistant conveyor belt, the abrasion is less than 150 mm²

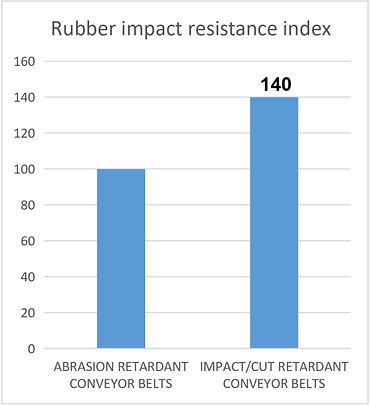

IMPACT/CUT RESISTANT (IMPACT/CUT RETARDANT) CONVEYOR BELT

SINOCONVE impact/cut resistant (impact/cut retardant) conveyor belts has excellent impact resistance, cut resistance and chipping resistance, and uses cover rubber. It is the perfect option for transporting sharp objects, such as rough stones, waste materials, logs, glass and iron flakes.

-

Impact Test Method

Testing machine : drop hammer impact testing machine

Cutting machine angle: 90° -

Cutting Resistance Test Method

Testing machine : Impact test by dropping a hammerWeight : 15Kg

Height : 400mm

Cutting machine angle: 90°

CHEVRON CONVEYOR BELT

Chevron conveyor belts are used on slope angles up to approx. 30º for slightly rolling materials such as gravel and coal and up to approx. 40º for sticky materials such as wet sand and earth. Patterned conveyor belts are also a highly effective belt for transporting packages such as sacks and bales.

Chevron Conveyor Belt Product Advantages

1. The conveyor belt is formed and vulcanised in one process together with the base pattern of the conveyor belt.

2. Conveyor belt allow the use of smaller pulley diameters.

3. High quality rubber cover with excellent material resistant to abrasion.

CHEVRON CONVEYOR BELT

SIDEWALL CONVEYOR BELT

Sidewall conveyor belts are composed of three parts: base belt, sidewall and cleats

Possible to transport goods at steep angle with big capacity in a limited space.

Specially treated steel mesh is incorporated into the top cover and bottom cover, creating an excellent combination of longitudinal flexibility and transverse rigidity.

All steep angle conveyor belts are durable.

Sidewall is hot vulcanized on the base belt made of high-quality rubber to guarantee sidewall withstand highly stress and repeated flexing

Fabric inside sidewall perfectly combine flexibility and strength to effectively avoid torn.

Cleats are also hot vulcanized on the base

Belt Fabric inside cleats protect cleats from deformation caused by impact

Cleats are the main part to accommodate high capacity metres and steep angles.

Available with TC or TCS type

Special compound to avoid deformation caused by impact.

QUALITY CONTROL

Step 1: Raw Material Inspection

Rubber Compound Test

Moving die rheometer analyzes the characteristics of Rubber Compound

Factory EP Test

Tensile strength test and elongation test when broken

Step 2: Advance equipment to guarantee quality from the details

Calender process

4 rollers calender machine is able to stick rubber on both side of the fabric in one time. This can reduce the strength loss of the rubber during the process.

Forming Process

The forming tension is even between different plies, which can avoid wrinkled fabric and guarantee an even thickness of belt core

Step 3: Finished belts inspection

A dedicated inspection team works to inspect the surface and dimension of each conveyor belt. If any problem on conveyor belts are found, we will repair at once in our factory.

Length and Surface Inspection

Thickness Inspection

Width Inspection

Step 4 : Technical Data Test

All raw materials and rubber compound are tested in our lab. For each roll of conveyor belt, the lab will test the following features, and issue Quality Test Report.

Abrasion Test

Adhesion Strength Test

Tensile Strength Test

Step 5 : Issue quality test report

The above test results are related to laboratory samples